Dipatlisiso bakeng sa Lethathamo la Ditheko

Bakeng sa lipotso mabapi le lihlahisoa tsa rona kapa lethathamo la litheko, ka kopo re siele lengolo-tsoibila la hau 'me re tla ikopanya le rona nakong ea lihora tse 24.

•Ho thibela ho petsoha ha likarolo tsa GRC

•Botšepehi bo Botle le ho se be le motlakase o sa fetoheng

•Fuzz e tlase

•E ntle haholo e kopantsoeng le samente

•Samente e ntle e tenyetsehang le e ntle ea kabo ea likhoele

•Ke bile le thepa e ntle ea 'mele le ea lik'hemik'hale bakeng sa GRC

• Hasana ka Potlako

•Litekanyo tse Tlase

•Ha e kotsi

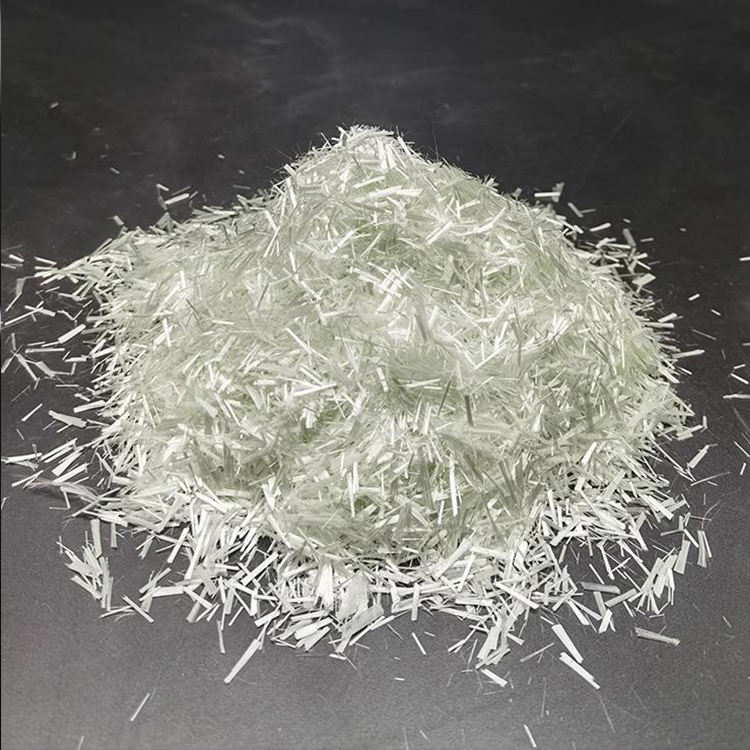

Ho etsa kopo bakeng saKhalase ea Fiber Samente/Konkreite e Matlafalitsoeng

Taelo ea Tšebeliso:

(1) Khoele e khaotsoeng ea Fiberglass e tsoakiloeng esale pele

Thepa:

E na le thepa e ntle haholo e nang le ho hanyetsa alkali, ho tiea, boemo ba ho bokellana, le ho se tsofale, e kopantsoe metsotso e 20 ka samenteng ka lebelo la 50rpm, e ntse e ka boloka boemo bo botle ba ho bokellana, 'me e ke ke ea hasana ho ea ho khoele.

Morero:

Ke botšepehi bo phahamengKhoele e khaotsoeng ea Faeba ea Khalasee etselitsoeng ho sebelisoa ho matlafatsa konkreite, li-render le li-mortar. E ka eketsoa ho ea setsoMetswako ebang ke sebakeng seo kapa ka ho e lokisa ka dikarolo tse ding tse ommeng tsa motswako. Dithapo tsa low-tex di dumella ho matlafatswa ho sebetsang hantle ka tekanyo e tlase. Di loketse haholo ho fetolwa ha metswako e tloaelehileng ya konkreite bakeng sa di-screed tsa fatshe le di-slab, le bakeng sa ho lokisa metswako e kentsweng mekotleng ya di-mortar le di-render tse ikgethang.

(2) Likhoele tse khaotsoeng tsa Fiberglass tse hasantsoeng ka metsi

Thepa:

Khalase ea khalase ea elektroniki Ha di sebediswa ka boholo bo hasantsweng ka metsi, dikhoele di tla hasana hantle ho ya ho di-filament tse ka metsing ka metsotswana e 10, mme di tla hasana ka potlako, tshebediso e fokotsehe, di eketse matla.

Morero:

Hangata e sebelisoa ka tekanyo e tlase ea ho eketsa ho thibela ho petsoha le ho ntlafatsa ts'ebetso ea konkreite e kopantsoeng e seng e loketse, li-screed tsa fatše, litšoantšo kapa metsoako e khethehileng ea seretse. E ka sebelisoa bakeng sa ho thibela ho petsoha ha bokaholimo ba GRC.

lihlahisoa.

HO SEBELISA:

--Kopanya resin ea hao le hardener, kapa catalyst

--E latelang, eketsa ya haoLikhoele tse khaotsoeng tsa Fiberglass

--Ho molemo ho sebelisa motsoako oa pente holim'a drile ea hau ea motlakase ho netefatsa hore likhoele tsohle li tletse hantle. Likarolo tse teteaneng le libaka tse kholo tsa ho tšela li ka baka mocheso o feteletseng, kahoo ela hloko.

Khoele e khaotsoeng ea Fiberglasss e lokela ho beoa tlas'a maemo a omileng 'me e se ke ea bula lera le koahelang ho fihlela e sebelisoa.

Lisebelisoa tsa phofo e omileng li ka bokellana litjhaja tse sa fetoheng, mehato e nepahetseng ea ho itšireletsa e lokela ho nkuoa ha ho na le lintho tse tukang.

Likhoele tse khaotsoeng tsa Fiberglass E ka baka ho teneha ha mahlo, e ka baka kotsi haeba e hema, e ka baka ho teneha ha letlalo, e ka baka kotsi haeba e metsoa. Qoba ho kopana le mahlo, le ho kopana le letlalo, Apara likhalase tsa mahlo le thebe ea sefahleho ha u e tšoara. Kamehla apara sesebelisoa se amohetsoeng sa ho hema. E sebelise feela ha moea o ntse o kena hantle. E boloke hole le mocheso. Hlase le lelakabe. Boloka mohele 'me u o sebelise ka tsela e fokotsang tlhahiso ea lerōle

Haeba e ka kopana le letlalo, e hlatsoe ka metsi a futhumetseng le sesepa. Bakeng sa mahlo, hlatswa ka metsi hang-hang metsotso e 15. Haeba ho teneha ho ntse ho tsoela pele, batla thuso ea bongaka. Haeba u e hema, e-ea sebakeng se hloekileng. Haeba u na le bothata ba ho hema, batla thuso ea bongaka hang-hang.

Setshelo se ka ba kotsi ha se se na letho—masalla a sehlahisoa sa setshelo a setshelo.

Lintlha tsa Bohlokoa tsa Tekheniki:

| CS | Mofuta oa Khalase | Bolelele bo khaotsoeng (mm) | Bophara(um) | MOL(%) |

| CS3 | Khalase ea elektronike | 3 | 7-13 | 10-20±0.2 |

| CS4.5 | Khalase ea elektronike | 4.5 | 7-13 | 10-20±0.2 |

| CS6 | Khalase ea elektronike | 6 | 7-13 | 10-20±0.2 |

| CS9 | Khalase ea elektronike | 9 | 7-13 | 10-20±0.2 |

| CS12 | Khalase ea elektronike | 12 | 7-13 | 10-20±0.2 |

| CS25 | Khalase ea elektronike | 25 | 7-13 | 10-20±0.2 |

Bakeng sa lipotso mabapi le lihlahisoa tsa rona kapa lethathamo la litheko, ka kopo re siele lengolo-tsoibila la hau 'me re tla ikopanya le rona nakong ea lihora tse 24.