Dipatlisiso bakeng sa Lethathamo la Ditheko

Bakeng sa lipotso mabapi le lihlahisoa tsa rona kapa lethathamo la litheko, ka kopo re siele lengolo-tsoibila la hau 'me re tla ikopanya le rona nakong ea lihora tse 24.

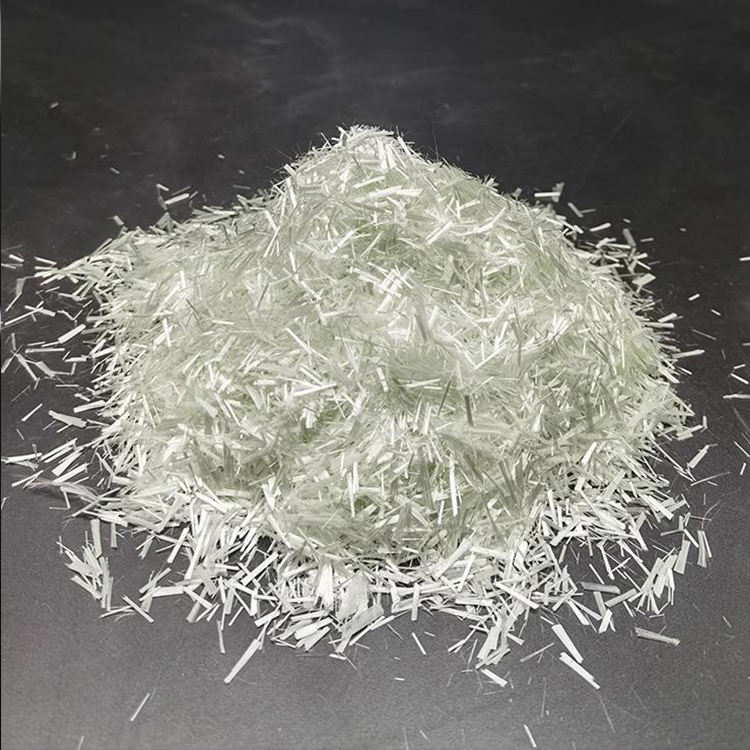

Likhoele tse khaotsoeng tsa fiberglass li na le litšobotsi le litšobotsi tse 'maloa. Tse ling tsa litšobotsi tsa bohlokoa li kenyelletsa:

Matla a Phahameng:Likhoele tse khaotsoeng tsa fiberglassli fana ka matla a ho tsitlella le ho tiea ha thepa e kopaneng eo li e matlafatsang.

Khanyetso ea Lik'hemik'hale:Li fana ka khanyetso e ntle ho lik'hemik'hale, mafome le ho senyeha ha tikoloho ha li kenngoa linthong tse kopaneng.

Ho Tsitsisa ha Thermal:Likhoele tse khaotsoeng tsa fiberglassli bontša ho hanyetsa mocheso o phahameng 'me li ka boloka thepa ea tsona mochesong o phahameng.

Ho kenya mocheso ka motlakase:Li fana ka thepa e ntle ea ho thibela ho ruruha ha motlakase, e leng se etsang hore li lokele ho sebelisoa likarolong tsa motlakase le tsa elektroniki.

E bobebe:Likhoele tse khaotsoeng tsa fiberglassli bobebe, li tlatsetsa boima bo tlase ka kakaretso le matla a phahameng a thepa e kopaneng.

Botsitso ba Tekanyo:Li thusa ho ntlafatsa botsitso ba boholo le ho hanyetsa ho thekesela ha thepa e kopaneng eo li e matlafatsang.

Ho lumellana:Likhoele tse khaotsoengli etselitsoe ho lumellana le litsamaiso tse fapaneng tsa resin, ho netefatsa ho khomarela hantle le ts'ebetso e kopaneng ka kakaretso.

Matlotlo ana a etsa horelikhoele tse khaotsoeng tsa fiberglasse na le mesebetsi e mengata ebile e bohlokoa bakeng sa mefuta e mengata ea lits'ebetso liindastering tse kang tsa likoloi, tsa kaho, tsa lifofane, tsa likepe, le tse ling.

Likhoele tse khaotsoeng tsa fiberglassli sebelisoa haholo tlhahisong ea mefuta e mengata ea thepa e kopantsoeng. Li sebelisoa liindastering tse fapaneng ho kenyeletsoa likoloi, lifofane, likepe, kaho le thepa ea bareki. Litšebeliso tse ling tse ikhethileng tsa likhoele tse khaotsoeng tsa fiberglass li kenyelletsa:

Likarolo tsa Likoloi:Likhoele tse khaotsoeng tsa fiberglassli sebelisoa ho etsa likarolo tse kang li-bumper, liphanele tsa 'mele, le likarolo tsa kahare bakeng sa likoloi, moo matla a tsona a phahameng le thepa ea tsona e bobebe li nkoang e le tsa bohlokoa.

Meaho ea Lifofane:Li sebelisoa ho hlahiseng likarolo tsa lifofane ka lebaka la matla a tsona, ho tiea ha tsona le ho hanyetsa mocheso le lik'hemik'hale.

Indasteri ea Likepe:Likhoele tse khaotsoeng tsa fiberglasshangata li sebelisoa ho aha li-hull tsa likepe, li-deck, le likarolo tse ling tsa leoatle ka lebaka la ho hanyetsa metsi le mafome.

Lisebelisoa tsa Kaho:Li sebelisoa ho hlahiseng thepa e fapaneng ea kaho joalo ka liphaephe, liphanele le li-reinforcement ka lebaka la ho tšoarella ha tsona le thepa ea tsona e hanelang boemo ba leholimo.

Thepa ea Bareki:Likhoele tse khaotsoeng tsa fiberglassli boetse li sebelisoa thepa ea bareki e kang lisebelisoa tsa lipapali, thepa ea ka tlung le li-enclosure tsa elektroniki ka lebaka la matla a tsona le ho boloka litšenyehelo.

Ka kakaretso,likhoele tse khaotsoeng tsa fiberglasske thepa e feto-fetohang e sebelisoang haholo tlhahisong ea thepa e kopaneng ho ntlafatsa thepa ea eona ea mechini le ea 'mele bakeng sa lits'ebetso tse fapaneng.

Likhoele tse khaotsoeng tsa fiberglassli lokela ho bolokoa maemong a omileng 'me lera le koahelang ha lea lokela ho buloa ho fihlela li se li loketse ho sebelisoa.

Lisebelisoa tsa phofo e ommeng li na le monyetla oa ho bokella litefiso tse sa fetoheng, kahoo ho bohlokoa ho nka mehato e hlokahalang ea ho itšireletsa ha u sebetsana le lintho tse chesoang.

Likhoele tse khaotsoeng tsa Fiberglassdi na le monyetla wa ho baka ho teneha ha mahlo le letlalo, hammoho le ditlamorao tse kotsi haeba di hema kapa di metsoa. Ho bohlokwa ho qoba ho kopana le mahlo le letlalo le ho roala digalase tsa mahlo, thebe ya sefahleho, le sesebelisoa se dumelletsweng sa ho hema ha o sebetsana le thepa ena. Ho feta moo, etsa bonnete ba hore o kenya moya hantle, qoba ho pepesehela mocheso, ditlhase le malakabe, mme o tshware le ho boloka thepa ka tsela e fokotsang tlhahiso ya lerōle.

Haeba ntho eo e kopana le letlalo, e hlatswe ka metsi a futhumetseng le sesepa. Haeba e kena mahlong, e hlatswe ka metsi metsotso e 15. Haeba ho teneha ho ntse ho tswela pele, batla thuso ya bongaka. Haeba o e hema, fallela sebakeng se nang le moya o hlwekileng, mme o batle thuso ya bongaka hanghang haeba o na le bothata ba ho hema.

Lijana tse se nang letho li ka ’na tsa e-ba kotsi ka lebaka la masalla a sehlahisoa.

Lintlha tsa Bohlokoa tsa Tekheniki:

| CS | Mofuta oa Khalase | Bolelele bo khaotsoeng (mm) | Bophara(um) | MOL(%) |

| CS3 | Khalase ea elektronike | 3 | 7-13 | 10-20±0.2 |

| CS4.5 | Khalase ea elektronike | 4.5 | 7-13 | 10-20±0.2 |

| CS6 | Khalase ea elektronike | 6 | 7-13 | 10-20±0.2 |

| CS9 | Khalase ea elektronike | 9 | 7-13 | 10-20±0.2 |

| CS12 | Khalase ea elektronike | 12 | 7-13 | 10-20±0.2 |

| CS25 | Khalase ea elektronike | 25 | 7-13 | 10-20±0.2 |

Bakeng sa lipotso mabapi le lihlahisoa tsa rona kapa lethathamo la litheko, ka kopo re siele lengolo-tsoibila la hau 'me re tla ikopanya le rona nakong ea lihora tse 24.