Dipatlisiso bakeng sa Lethathamo la Ditheko

Bakeng sa lipotso mabapi le lihlahisoa tsa rona kapa lethathamo la litheko, ka kopo re siele lengolo-tsoibila la hau 'me re tla ikopanya le rona nakong ea lihora tse 24.

Ho solla ka ho toba e etsoa ka tex kapa yield e hlalositsoeng hantle mme e sebediswa haholoholo e le seabo bakeng sa ditshebetso tsa ho loha. E fana ka ho phutholoha ha bonolo ka lebaka la kgatello e lekanang, tlhahiso e fokolang ya fuzz, le ho kgona ho koloba hantle haholo. E ka boela ya sebediswa ditheknolojing tse fapaneng tsa ditshebetso tse kang pultrusion kapa filament winding.

Ho solla ka ho tobae phekoloa ka boholo bo thehiloeng ho silane nakong ea tlhahiso ho netefatsa hore e lumellana le li-thermosets tse kang UP (unsaturated polyester), VE (vinyl ester), le li-resin tsa epoxy. Kalafo ena e lumellaho solla ka ho tobaho bontša thepa e ntle ea mechini le ho hanyetsa lik'hemik'hale, e leng se etsang hore e lokele mefuta e mengata ea lits'ebetso.

Fiberglass e otlolohileng e sothake mofuta oa ho potoloha ka lehlakoreng le le leng ho entsoeng ka E-Glass, e nang le litšobotsi tse 'maloa tsa bohlokoa.

1. Matlotlo ana a kenyeletsa ho se be le maqhama, ho se be le maqhama a mangata, le ho ba le maqhama a matle a ho kobeha le ho loha mahlakoreng a kobehileng le a tlatsitsoeng.

2. Ho bonolo ho e kenya ka lebaka la ho hloka ho sotha. Ho na le litsamaiso tse fapaneng tsa boholo tse fumanehang, e 'ngoe le e 'ngoe e na le litšobotsi tse ikhethang joalo ka ho lumellana hantle le li-resin tse fapaneng le ho hanyetsa tikoloho ea alkaline.

3.Ho sollae boetse e fana ka melemo e kang ho tsamaisa mocheso o tlase, ho hanyetsa mollo, ho lumellana le matrices ea tlhaho, ho thibela motlakase, le botsitso ba litekanyo.

4. Ha e a lokela ho sebediswa bakeng sa dikopo tsa mocheso o phahameng mme ha e bola. Ho rarolla mefokolo ena, bahlahisi ba ka kenyelletsa thepa e meng kapa ditlatsetso ka hara matrix e kopaneng ho ntlafatsa khanyetso ya tshusumetso le ho tiya, ho ntlafatsa kgomarelo ya faeba-matrix, le ho eketsa matla a ho kuta a interfacial.

5.Fiberglass e otlolohileng e sothae tenyetseha haholo.

Ho batla mohloli o tšepahalang oaFiberglass e otlolohileng e sothaSe shebe hole! Tsa ronaFiberglass e otlolohileng e sothae etsoa ka theknoloji e tsoetseng pele le thepa ea boleng bo holimo, e netefatsang ts'ebetso e ikhethang le ho tšoarella. E etselitsoe mefuta e mengata ea lits'ebetso, ea ronaFiberglass e otlolohileng e sothae fana ka thepa e ntle haholo ea ho ntša metsi, e nolofalletsang ho kenngoa ha resin ka mokhoa o motle bakeng sa matla a eketsehileng le ho tiea. Hore na u e hloka bakeng sa tlhahiso ea metsoako, pultrusion, filament winding, kapa lits'ebetsong tse ling, ea ronaFiberglass e otlolohileng e sothake khetho e phethahetseng. Ikopanye le rona kajeno ho ithuta haholoanyane ka ronaFiberglass e otlolohileng e sotha'me u fumane hore na e ka phahamisa ts'ebetso ea hau ea tlhahiso joang ho ea maemong a macha.

Fiberglass e tsamaeang ka ho tobaE bonts'a ts'ebetso e ntle ea ts'ebetso le ho futhumala ho tlase, e leng se etsang hore e lokele lits'ebetso tse kang litanka tsa FRP, litora tse pholisang, lisebelisoa tsa mohlala, li-shed tsa lithaele tsa mabone, likepe, lisebelisoa tsa likoloi, merero ea ts'ireletso ea tikoloho, thepa e ncha ea kaho ea marulelo, libate, le tse ling. E fana ka khanyetso e ntle ea ho bola ha asiti, khanyetso ea botsofali, le thepa ea mechini, e leng se etsang hore e be thepa e tšepahalang bakeng sa lits'ebetso tse fapaneng tsa indasteri le tsa kaho.

Ntle le thepa ea eona ea mechine, ho sotha ka kotloloho ho tsamaisana le litsamaiso tse ngata tsa resin, ho netefatsa hore metsi a tsoa ka botlalo le ka potlako. Sena se etsa hore e lokele ho sebelisoa mahlaleng a fapaneng a ts'ebetso, joalo ka pultrusion kapa filament winding. Ts'ebeliso ea metsoako ea tšebeliso ea ho qetela eafiberglass e tsamaeang ka ho tobae ka fumanoa meralong ya motheo, meahong, metsing, dipapading le boikhathollong, le dipalangwang tsa metsing.

Ka kakaretso,fiberglass e tsamaeang ka ho tobake thepa e feto-fetohang e fumanang ts'ebeliso liindastering le lihlahisoa tse fapaneng ka lebaka la ho lumellana ha eona le litsamaiso tse fapaneng tsa resin, thepa e ntle ea mechini, le ho hanyetsa mafome le botsofali.

| Mofuta oa Khalase | Ho letsa ka ho toba ka khalase ea fiberglass ea E6 | ||||||||

| Mofuta oa Boholo | Silane | ||||||||

| Khoutu ea Boholo | 386T | ||||||||

| Botenya ba Mothapo(tex) | 300 | 200 400 | 200 600 | 735 900 | 1100 1200 | 2000 | 2200 | 2400 4800 | 9600 |

| Bophara ba filthara (μm) | 13 | 16 | 17 | 17 | 17 | 21 | 22 | 24 | 31 |

| Botenya ba Mothapo (%) | Mongobo (%) | Boholo ba Dikahare (%) | Matla a ho Robeha (N/Tex) ) |

| ISO 1889 | ISO3344 | ISO1887 | ISO3341 |

| ± 5 | ≤ 0.10 | 0.60 ± 0.10 | ≥0.40(≤2400tex)≥0.35(2401~4800tex)≥0.30(>4800tex) |

| Matlotlo a Mekaniki | Yuniti | Boleng | Resin | Mokhoa |

| Matla a tšepe | MPa | 2660 | UP | ASTM D2343 |

| Modulus ea Tensile | MPa | 80218 | UP | ASTM D2343 |

| Matla a ho kuta | MPa | 2580 | EP | ASTM D2343 |

| Modulus ea Tensile | MPa | 80124 | EP | ASTM D2343 |

| Matla a ho kuta | MPa | 68 | EP | ASTM D2344 |

| Ho boloka matla a ho beola (ho bela ha dihora tse 72) | % | 94 | EP | / |

Memo:Lintlha tse ka holimo ke boleng ba 'nete ba liteko bakeng sa E6DR24-2400-386H' me ke tsa litšupiso feela.

| Bophahamo ba sephutheloana mm (ka hare) | 255(10) | 255(10) |

| Sephutheloana ka hare ho bophara ba mm (ka hare) | 160 (6.3) | 160 (6.3) |

| Sephutheloana sa bophara bo kantle mm (ka hare) | 280(1)1) | 310 (12.2) |

| Boima ba sephutheloana kg (lb) | 15.6 (34.4) | 22 (48.5) |

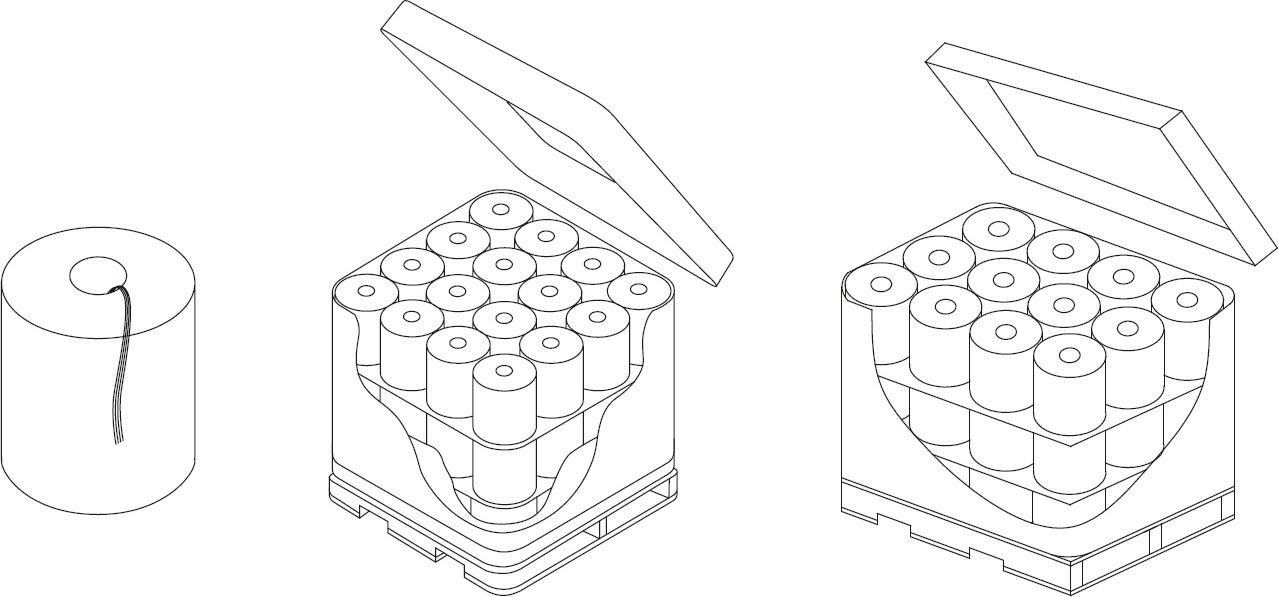

| Palo ea mekhahlelo | 3 | 4 | 3 | 4 |

| Palo ea li-doff ka lera | 16 | 12 | ||

| Palo ea li-doff ka pallet | 48 | 64 | 36 | 48 |

| Boima ba 'nete ka pallet kg (lb) | 750 (1653.5) | 1000 (2204.6) | 792 (1746.1) | 1056 (2328.1) |

| Fiberglass e otlolohileng e sothaBolelele ba palete mm (ka hare) | 1120 (44.1) | 1270 (50.0) | ||

| Fiberglass e otlolohileng e sothaBophara ba palete mm (ka hare) | 1120 (44.1) | 960 (37.8) | ||

| Fiberglass e otlolohileng e sothaBophahamo ba palete mm (ka hare) | 940 (37.0) | 1200 (47.2) | 940 (37.0) | 1200 (47.2) |

• Ntle le haeba ho boletsoe ka tsela e 'ngoe,lihlahisoa tsa fiberglasse lokela ho bolokoa sebakeng se omileng, se pholileng le se sa keneleng mongobo.

•Lihlahisoa tsa fiberglasse lokela ho lula hofiberglass e tsamaeang ka ho tobaSephutheloana sa pele ho fihlela pele se sebelisoa. Mocheso oa kamore le mongobo li lokela ho bolokoa ho -10℃ ~ 35℃ le ≤80% ka ho latellana.

• Ho netefatsa polokeho le ho qoba tšenyo sehlahisoang, liphalete ha lia lokela ho beoa ka holim'a bophahamo ba mekato e fetang e meraro.

• Ha diphalete di bewa ka mekhahlelo e 2 kapa e 3, tlhokomelo e kgethehileng e lokela ho nkuwa ho tsamaisa phalete e ka hodimo ka nepo le ka thelelo.

Bakeng sa lipotso mabapi le lihlahisoa tsa rona kapa lethathamo la litheko, ka kopo re siele lengolo-tsoibila la hau 'me re tla ikopanya le rona nakong ea lihora tse 24.