Selelekela

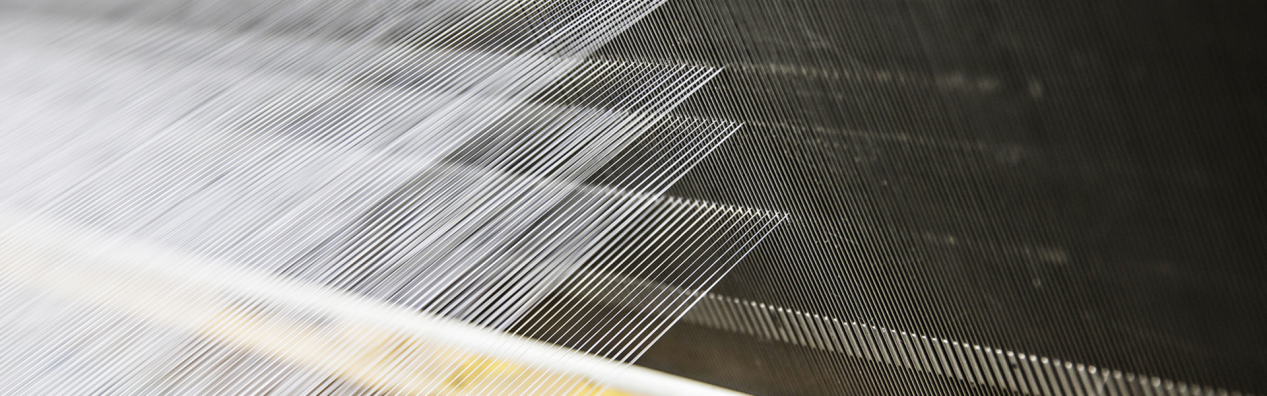

Ha tlhoko ea matla a tsosolositsoeng e ntse e hola, matla a moea a ntse a tsoela pele ho ba tharollo e ka sehloohong bakeng sa tlhahiso ea motlakase e tsitsitseng. Karolo ea bohlokoa ea liturbine tsa moea ke hore lehare, leo e lokelang ho ba le boima bo bobebe, le tšoarelle, 'me le se ke la angoa ke lintho tse bakang khatello ea tikoloho. Fho solla ka khalase ea iberglasse hlahile e le thepa ea bohlokoa tlhahisong ea lehare la turbine ka lebaka la kamano ea eona e phahameng ea boholo ba matla le boima, ho hanyetsa mafome le katleho ea litšenyehelo.

Sehlooho sena se hlahloba litlhohonolofatso tsa bohlokoa tsaho qamaka ha fiberglasska har'a mahare a turbine, totobatsa hore na ke hobane'ng ha e ntse e le mokhoa o tsebahalang haholo bakeng sa baetsi le tsela eo e kenyang letsoho ka eona matleng le bophelong bo bolelele ba litsamaiso tsa matla a moea.

1. Karolelano e Phahameng ea Matla ho ea ho Boima e Ntlafatsa Tshebetso

E 'ngoe ea melemo ea bohlokoa ka ho fetisisa eaho qamaka ha fiberglasske karolelano ea eona e ikhethang ea matla-ho-boima. Mahare a turbine ea moea a tlameha ho ba bobebe ho fokotsa mojaro sebopehong sa turbine ha ka nako e ts'oanang a boloka matla a ho tsitlella ho mamella matla a moea.

Ho solla ha fiberglasse fana ka matla a matle a mechini, e leng se lumellang makhapetla ho mamella lebelo le phahameng la moea ntle le ho fetoha.

Ha ho bapisoa le thepa ea setso joalo ka tšepe,fiberglasse fokotsa boima ba lehare, e ntlafatsa bokgoni ba ho sebedisa matla le ho fokotsa ho tsofala ha dikarolo tsa turbine.

Tlhaho e bobebe eafiberglasse nolofalletsa meralo ea mahare a malelele, e hapa matla a moea a mangata le ho eketsa tlhahiso ea matla.

Ka ho ntlafatsa tekano pakeng tsa boima le matla,ho qamaka ha fiberglasse thusa ho eketsa tshebetso ya turbine ha ka nako e ts'oanang e fokotsa kgatello ya sebopeho.

2. Khanyetso e Phahameng ea Mokhathala bakeng sa Bophelo bo Bolelele

Mahare a turbine ea moea a lula a jarisoa ka potoloho ka lebaka la lebelo le fapaneng la moea le liphetoho tse lebisang moo ho hlokahalang. Ha nako e ntse e ea, sena se ka lebisa mokhathaleng oa thepa le ho hloleha ha sebopeho haeba se sa rarolloe hantle.

Ho solla ha fiberglasse na le ho hanyetsa mokhathala haholo, ho bolelang hore e ka mamella lipotoloho tse limilione tsa khatello ea maikutlo ntle le ho senyeha ho hoholo.

Ho fapana le litšepe, tse ka bang le mapetso a manyenyane ha nako e ntse e ea, fiberglass e boloka botsitso ba eona tlas'a matla a kobehang a pheta-phetoang le a ho phethoha.

Ho tiea hona ho eketsa nako ea mahare a turbine, ho fokotsa litheko tsa tlhokomelo le nako.

Bokhoni bafiberglassho hanela mokhathala ho netefatsa ho tšepahala ha nako e telele, e leng se etsang hore e be tharollo e theko e tlaase bakeng sa lits'ebetso tsa matla a moea.

3. Tshenyo le Khanyetso ya Tikoloho

Liturbine tsa moea li pepesetsoa maemo a thata a tikoloho, ho kenyeletsoa mongobo, mahlaseli a UV, metsi a letsoai (libakeng tse hoketsoeng lebōpong la leoatle), le ho feto-fetoha ha mocheso. Thepa ea setso joalo ka tšepe e kotsing ea ho bola, e hlokang tlhokomelo khafetsa.

Ho solla ha fiberglasse hanela mafome ka tlhaho, e leng se etsang hore e be ntle bakeng sa mapolasi a moea a lebōpong la leoatle le a lebōpong la leoatle.

Ha e ruse kapa hona ho bola ha e pepesetsoa metsi, mongobo, kapa spray ea letsoai, ho fapana le mekhoa e meng ea tšepe.

Liaparo tse hananang le mahlaseli a kotsi a UV li ka ntlafatsa bokhoni ba fiberglass ba ho mamella ho pepesehela letsatsi nako e telele.

Ho hanyetsa hona mabaka a tikoloho ho netefatsa hore mahare a matlafalitsoeng ke fiberglass a lula a sebetsa ebile a sebetsa hantle ka mashome a lilemo, esita le maemong a leholimo a mabifi.

4. Ho Sebetsa ka Botlalo le Bokgoni ba ho Etsa Dihlahiswa

Ho hlahisa mahare a turbine ea moea ho hloka thepa e seng feela e matla le e tšoarellang empa hape e le e theko e tlaase ho etsoa ka tekanyo e kholo.

Ho solla ha fiberglasse theko e tlase ho feta faeba ya khabone ha e ntse e fana ka tshebetso e tshwanang bakeng sa dikopo tse ngata.

Thepa ena e bonolo ho e sebetsana nakong ea ts'ebetso ea tlhahiso, e leng se lumellang tlhahiso e potlakileng ea mahare a kopaneng ho sebelisoa mekhoa e kang ho kobeha ha filament le pultrusion.

Ho tenyetseha ha eona moralong ho nolofalletsa bahlahisi ho ntlafatsa libopeho tsa lehare bakeng sa aerodynamics e betere ntle le tšenyo e ngata ea thepa.

Ka ho fokotsa litšenyehelo tsa tlhahiso le ho ntlafatsa katleho ea tlhahiso,ho qamaka ha fiberglasse thusa ho etsa hore matla a moea a sebetse hantle haholoanyane moruong.

5. Ho Tenyetseha ha Moralo bakeng sa Aerodynamics e Ntlafalitsoeng

Bokgoni ba ho fofa ha maqhubu a turbine ya moya bo ama ka ho toba tlhahiso ya matla.Ho solla ha fiberglasse dumella ho tenyetseha ho hoholo ha moralo, e leng se nolofalletsang baenjiniere ho etsa di-blade tse nang le dibopeho tse ntle ka ho fetisisa bakeng sa ho hapa moya ka ho fetisisa.

Metswako ea khalase ea fiberglasse ka bōptjoa hore e be li-geometri tse rarahaneng, ho kenyeletsoa le meralo e kobehileng le e fokolang, e ntlafatsang ho phahamisa le ho fokotsa ho hula.

Ho ikamahanya ha thepa ho tshehetsa boqapi ba bolelele le sebopeho sa lehare, e leng se tlatsetsang tlhahisong e phahameng ya matla.

Mekhoa ea faeba e ka fetoloang e ntlafatsa ho satalla le kabo ea mojaro, e thibela ho hloleha pele ho nako.

Ho tenyetseha hona ha moralo ho netefatsa hore mahare a matlafaditsweng ka fiberglass a ka lokisetswa maemo a itseng a moya, e leng se ntlafatsang bokgoni ba turbine ka kakaretso.

6. Ho Tšoarella le ho Sebelisa Hape

Ha indasteri ea matla a moea e ntse e hola, botsitso khethong ea thepa bo ntse bo ba bohlokoa haholo.Ho solla ha fiberglasse fana ka melemo ea tikoloho ha e bapisoa le mekhoa e meng e sa ntjhafatseng.

Tlhahiso ea fiberglass e ja matla a fokolang ho feta litšepe tse kang tšepe kapa aluminium, e leng se fokotsang khabone e sebelisoang tlhahisong ea mahare.

Tsoelo-pele ea theknoloji ea ho sebelisa lintho hape e etsa hore metsoako ea fiberglass e tšoarelle haholoanyane, ka mekhoa ea ho sebelisa hape mahare a qetello ea bophelo hore e be thepa e ncha.

Ka ho eketsa nako ea bophelo ba lehare, fiberglass e fokotsa makhetlo a ho nkeloa sebaka, e leng se fokotsang litšila.

Litšobotsi tsena tse sireletsang tikoloho li tsamaisana le boitlamo ba lekala la eneji e nchafatsoang ba ho boloka tikoloho e le teng.

Qetello

Ho solla ha fiberglasse bapala karolo ea bohlokoa ts'ebetsong, ho tšoarella le ho boloka litšenyehelo tsa mahare a turbine ea moea. Kamano ea eona e phahameng ea bongata ho tloha ho boima ho ea ho matla, ho hanyetsa mokhathala, tšireletso ea mafome le ho tenyetseha ha setaele.etsake thepa ea bohlokoa khoebong ea matla a moea.

Ha diturbine tsa moya di ntse di hola ka boholo le bokgoni, tlhoko ya thepa e tswetseng pele ya motswako jwalo kaho qamaka ha fiberglasse tla eketseha feela. Ka ho sebelisa melemo ea eona ea bohlokoa, bahlahisi ba ka hlahisa mahare a tšoarellang nako e telele le a sebetsang hantle haholoanyane, ba khanna bokamoso ba matla a tšoarellang.

Bakeng sa bahlahisi ba mapolasi a moea le bahlahisi ba li-turbine, ho tsetela boleng bo holimoho qamaka ha fiberglasse netefatsa di-blade tse tshepahalang, tse sebetsang hantle tse eketsang tlhahiso ya matla ha ka nako e ts'oanang di fokotsa ditjeo tsa tshebetso.

Nako ea poso: Mots'eanong-06-2025