1.Ts'ebetso ea ho phalla

Ho tlosa litšitiso → ho ala le ho hlahloba mela → ho hloekisa bokaholimo ba sekontiri ka lesela le khomarelanglesela la carbon fiber→ tšireletso ea bokaholimo → ho etsa kopo ea tlhahlobo.

2. Mokhoa oa ho haha

2.1 Ho tlosa litšitiso

2.1.1 Hloekisa ho latela maemo a teng setšeng.Molao-motheo o akaretsang ke ho nolofatsa kaho.

2.1.2 Bahlahlobi ba boleng ba setšeng ba hlahloba boemo ba ho hloekisa, 'me ba fetela mohatong o latelang ka mor'a ho feta tlhahlobo.

2.2Ho lefa le ho hlahloba mohala

2.2.1 Lokolla lesela la carbon fiber peista position line point point line

2.2.2 Kaho e ka qalisoa feela ka mor'a hore setsebi sa setšeng (foreman) se hlahlobe le ho lokolla mohala ka nepo.

2.3 Hloekisa sebopeho sa konkreite holim'a lesela la fiber ea carbon

2.3.1 Sila bokaholimo ba konkreite ka grinder ea angle

2.3.2 Sebelisa se omisa moriri ho bululela lerole holim'a konkreite

2.3.3 Party A, mookamedi le motho ya okametseng rakonteraka e akaretsang ba kopuwa ho hlahloba le ho amohela bokahodimo ba konkreite bo bentshitsweng.

2.4 Lokisetsa 'me u sebelise primer

2.4.1 Beha boima ba 'mele ka mokhoa o nepahetseng ho latela tekanyo e boletsoeng ke moemeli ea ka sehloohong le moemeli ea phekolang oa resin e tšehetsang, e kenye ka har'a setshelo,' me ue tsose ka ho lekana ka motsoako.

2.5 Ho leka-lekanya bokaholimo ba sebopeho sa konkreite

2.5.1 Tlatsa likarolo tsa concave holim'a likarolo ka epoxy putty 'me u li lokise sebakeng se boreleli.Ha o sebelisa epoxy putty ho lokisa sekoli, e lokela ho hahoa tlas'a maemo a mocheso ka holimo ho -5 ℃ le mongobo o lekanyelitsoeng o ka tlase ho 85%.Ka mor'a hore putty e kenngoe le ho hlajoa, mela e mene ea convex e ntseng e le teng holim'a metsi e lokela ho lokisoa ka sandpaper, 'me likhutlo li lokela ho lokisoa ho arc e nang le radius e seng ka tlase ho 30mm.

2.6 Beha fiber ea carbonlesela

2.6.1 Pele o maneha disebediswa tsa carbon faeba, netefatsa pele hore bokahodimo bo omme.Ha mocheso o ka tlase ho -10 ℃ le mongobo o lekanyelitsoeng RH> 85%, kaho ha e lumelloe ntle le mehato e sebetsang.E le ho thibela carbon fiber hore e se ke ea senyeha, sebelisa rulara ea tšepe le thipa ea wallpaper ho khaola thepa ea carbon fiber ka boholo bo boletsoeng pele ho peista, 'me bolelele ba karolo ka' ngoe hangata ha bo fete 6m.E le ho thibela thepa hore e se ke ea senyeha nakong ea polokelo, palo ea ho itšeha ea thepa e lokela ho khaoloa ho latela palo ea letsatsi.Bolelele ba lirope tsa carbon fiber longitudinal joints ha boa lokela ho ba ka tlase ho 100mm.Karolo ena e lokela ho tlotsoa ka resin e ngata, 'me fiber ea carbon ha e hloke hore e kopane ka holimo.

2.6.2 Lokisetsa resin e kenyang 'me u e sebelise ka mokhoa o ts'oanang ho likarolo tse lokelang ho kenngoa.Botenya ba sekhomaretsi ke 1-3mm, 'me bohareng bo teteaneng' me mathōko a tšesaane.

2.6.3 Ho thetheha haufi le tataiso ea fiber ka makhetlo a mangata ho pepeta li-bubble tsa moea, e le hore resin e kentsoeng e ka phunyeletsa ka ho feletseng lesela la fiber.

2.6.4 Bokaholimo ba lesela la carbon fiber le koahetsoe ka ho lekana ka resin e emeng.

2.7 Kalafo ya tshireletso ya sefahleho

2.7.1 Haeba lisebelisoa tse matlafatsang le tse matlafatsang li hloka hore li se ke tsa chesoa, ho ka sebelisoa seaparo se thibelang mollo ka mor'a hore resin e phekoloe.Ho roala ho lokela ho etsoa ka mor'a phekolo ea pele ea resin, 'me e lokela ho lumellana le litekanyetso tse amehang le melao ea kaho ea seaparo se sebelisitsoeng.

2.8 Kopo ea tlhahlobo

2.8.1 Kamora ho phethoa, ka kopo okamele kapa rakonteraka ka kakaretso bakeng sa kamohelo.Tlatsa lintlha tse patiloeng tsa tlhahlobo, foromo ea tumello ea tlhahlobo ea boleng ba projeke, ka kopo saena rakonteraka le mookameli

2.8.2 Hlophisa lintlha tsohle tse hlokahalang bakeng sa morero le ho li fetisetsa ho mokonteraka ea akaretsang ho netefatsa botšepehi ba lintlha tsohle tsa morero.

3. Litekanyetso tsa boleng ba kaho

3.1 Morero oa mantlha oa taolo:

Lesela le pentiloeng la carbon fiber le tlameha ho finyella litlhoko tsa moralo le litlhaloso tsa kaho ea indasteri ea matlafatso

3.2 Lintho tse akaretsang:

3.1

3.2.2 Haeba ho na le tse fetang 10 ka square meter, e nkoa e sa tšoanelehe 'me e hloka ho lokisoa.

3.2.3 Bakeng sa meropa e sekoti e bophara ba ho feta 30mm, hafeela e ntse e hlaha, e nkoa e sa tšoanelehe 'me e hloka ho lokisoa.

4.Litlhokomelo bakeng sa kaho

4.1 Mehato ea ts'ireletso bakeng sa ho maneha lesela la faeba ea carbon

4.1.1 Likarolo tsa A le B tsa resin e tsamaellanang li lokela ho koaloa le ho bolokoa hole le mohloli oa mollo le ho qoba khanya ea letsatsi.

4.1.2 Basebelisi ba lokela ho apara liaparo tsa mosebetsi le limaske tse sireletsang.

4.1.3 Sebaka sa kaho se lokela ho ba le mefuta eohle ea litima-mollo tse hlokahalang bakeng sa pholoso.

4.2 Mehato ea tšireletso ea tšireletso

4.2.1 Sebakeng se kotsi, litšiea tse peli li tla beoa moeling, 'me lebone le khubelu le tla behoa bosiu.

4.2.2 Foreimi e 'ngoe le e 'ngoe ea kaho e tla hlongoa ho latela maemo a ts'ireletso ea tekheniki ea scaffolding le litlhaloso.

4.3 Mekhoa ea tsamaiso ea mollo

4.3.1 Ho matlafatsa mosebetsi oa ts'ireletso ea mollo setšeng sa morero ho netefatsa kaho le tlhahiso e tloaelehileng, le ho sireletsa polokeho ea maphelo a batho le thepa.

4.3.2 Libakete tsa ho tima mollo, litšepe, lihakisi, likharafu le lisebelisoa tse ling tsa ho tima mollo li lokela ho kenngoa setšeng.

4.3.3 Theha tsamaiso ea boikarabello ba ts'ireletso ea mollo maemong ohle, ho theha mokhoa oa ts'ireletso ea mollo, le ho laola ts'ebetsong ea eona e tiileng.

4.3.4 Theha mokhoa oa setifikeiti sa mollo bakeng sa ho etsa kopo ea malakabe a bulehileng, ho thibela ho tsuba sebakeng sa kaho, le ho laola mohloli oa mollo.

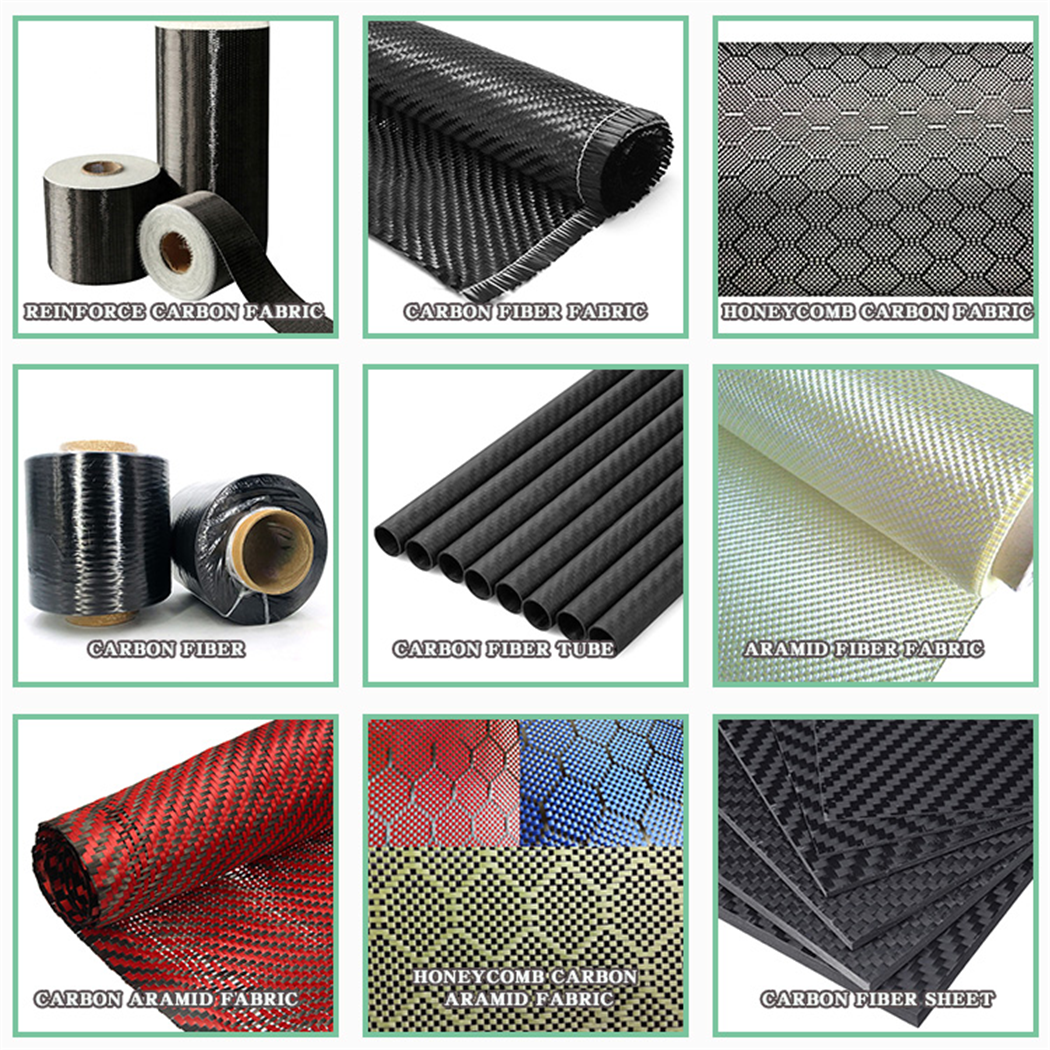

Mefuta ea lihlahisoa tsa rona tsa carbon fiber ke tse latelang:

Matlafatsa lesela la carbon

Clesela la fiber ea arbon 3k 200g

Lesela la carbon khekhe ea linotsi

Ho tsamaisa fiber ea carbon

Carbon fiber tube

Lesela la carbon aramid

Lekheha la linotšiclesela la aramide

Re boetse re hlahisafiberglass direct roving,limmete tsa fiberglass, letlooeng la fiberglass, lefiberglass e lohiloeng ka roving.

Ka kopo ikopanye le:

Nomoro ea mohala: +8615823184699

Nomoro ea mohala: +8602367853804

Email:marketing@frp-cqdj.com

Nako ea poso: May-18-2022